The deck height must be done before cutting the rail groove. Follow proper assembly instructions when assembling the PRC and use the supplied grease to grease the walls of the PRC. Make sure your blades are back before you bolt your frame to the CAR. Double check the threaded shaft moves freely by hand when tight. If your frame does not fit down inside the PRC do not force it, STOP and proceed to frame thinning before cutting rails.

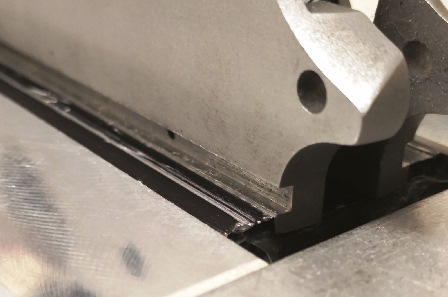

After the frame is bolted down, turn the threaded shaft until the frame is in the middle of the cutting gate (the 2 blades) Slowly turn the adjuster knobs until they lightly touch the frame (do this on both sides.)This is your “Zero point,” note each sides adjuster knob position by the white dot on the back (they might be different.) You’re ready to start cutting, while making a cutting pass do not stop in the middle of your cut, it will leave a dent in the groove. If you’re using a cordless drill, always cut at the low speed. You do not need to open the cutting gate when returning to the start position, just keep closing the blades every cutting pass. Each 1/4 turn of the adjuster knob will remove .003 of material per pass, per side. Use your supplied slide to get your final frame groove dimension it will be .062-.065 deep approx. It will take at least 5 full turns of the adjuster knob to get to your target depth. Use cutting oil on the blades and the frame and oil every full turn of the adjuster knob. Use a cordless drill on the threaded shaft to advance the frame forwards and back. When cutting, never take more than ¼ of a turn when cutting.